Thinking about bringing robots into your business but feeling a bit overwhelmed? You're not alone. The world of automation can seem pretty complex, with all sorts of jargon and technical bits. But what if there was a way to get started without all the fuss? That's where robotic turnkey solutions come in. They're basically pre-packaged automation systems designed to get you up and running quickly, making the whole process much simpler. Let's break down what that actually means and why it might be the perfect fit for you.

Key Takeaways

- Robotic turnkey solutions are pre-built, ready-to-use automation systems that simplify the integration of robots into your processes.

- They offer several advantages over custom setups, including faster deployment, reduced costs, and lower project risks because they are pre-tested.

- Turnkey systems come in various forms, such as robotic arms with pre-set software, autonomous mobile robots for moving goods, and integrated systems for specific jobs like packaging.

- Choosing the right turnkey solution involves understanding your automation goals, considering your budget and timeline, and ensuring it works with your existing equipment.

- Popular brands like Fanuc, Techman, and Universal Robots support turnkey automation, making it easier to find compatible and reliable systems for your business needs.

Understanding Robotic Turnkey Solutions

What Constitutes A Turnkey Solution?

So, what exactly is a robotic turnkey solution? Think of it like buying a pre-built shed instead of gathering all the wood, nails, and tools yourself and trying to follow a complicated blueprint. A turnkey system is essentially a ready-to-go package. It’s a complete, pre-engineered setup designed for a specific job, and it's meant to be installed and used with minimal fuss. The idea is that you can 'turn the key' and it just works. It bundles all the necessary hardware, software, and sometimes even the basic programming needed for a particular task. This means you're not starting from scratch; the heavy lifting of designing and configuring the system has already been done by the provider. It’s about getting a functional robotic application without needing a whole team of engineers to build it from the ground up.The Core Components Of Turnkey Systems

These systems aren't just a robot arm sitting in a box. They typically include several key parts that work together. You'll usually find the robot itself, of course, but that's just the start. There's often a pre-built frame or base, safety features like guarding or light curtains, and the necessary end-of-arm tooling (that's the gripper or tool at the end of the robot's arm) designed for the specific task. Plus, all the control systems and software are integrated and tested. It’s a complete package, ready to be plugged into your production line. For example, a palletising turnkey solution might include the robot, a pallet dispenser, a conveyor, and the software to stack boxes efficiently. It’s all about having a cohesive unit that performs a defined function.

Ready To Use: The Turnkey Advantage

The main selling point for these solutions is their readiness. Unlike a custom-built system that can take months to design, build, and test, a turnkey solution is designed to be deployed much faster. This significantly cuts down on the time you spend waiting for automation to start. It means you can get your processes up and running quicker, which is a big deal when you're trying to boost production or meet deadlines. This speed is a major reason why many businesses are looking at industrial automation as a way to improve their operations without lengthy development cycles. The reduced complexity and pre-tested nature mean fewer surprises down the line, making it a more predictable path to automation.

Key Benefits Of Robotic Turnkey Solutions

When you're looking at bringing robots into your business, the idea of a 'turnkey' solution can sound pretty appealing. And honestly, it often is. These systems are designed to be ready to go pretty much straight out of the box, which cuts down on a lot of the usual hassle. Let's break down why that's a good thing for your operation.

Streamlined Integration Processes

Forget spending weeks or months trying to get new automation to play nicely with your existing setup. Turnkey solutions are pre-configured and tested, meaning they're built to slot in with minimal fuss. This drastically cuts down on the time and technical headaches involved in getting things up and running. The goal here is to get you operational faster, with less disruption to your day-to-day work.

Achieving Cost Efficiencies

While the initial price tag might seem a bit higher than cobbling something together yourself, the long-term savings are often substantial. You're not paying for endless hours of custom engineering or troubleshooting unexpected issues that pop up during a bespoke build. Think of it as paying for a proven, reliable system rather than a project that's still in development.

Minimising Project Risks

Custom automation projects can be a bit of a gamble. There's always a chance something won't work as planned, leading to delays and extra costs. Turnkey systems, on the other hand, have already had their kinks ironed out. They're designed and tested for specific tasks, so you're getting a solution that's proven to work. This means fewer surprises and a more predictable outcome for your investment.

Accelerated Deployment Timelines

Time is money, right? With a turnkey solution, you're not waiting around for lengthy design, build, and testing phases. Because the system is pre-engineered, it can be deployed much more quickly than a custom-built alternative. This allows you to start reaping the benefits of automation sooner, giving you a competitive edge.

The beauty of a turnkey robotic system lies in its completeness. It's not just a robot; it's a pre-packaged solution that includes the necessary hardware, software, and often the integration know-how, all designed to work together harmoniously from the moment it arrives.

Here's a quick look at what that means in practice:

- Reduced Engineering Load: Your team doesn't need to be robotics experts to implement the system.

- Predictable Performance: Systems are tested for specific applications, leading to reliable operation.

- Faster Time-to-Value: Get your automated processes running and see a return on your investment sooner.

Exploring Different Types Of Turnkey Solutions

Right then, so you're thinking about getting a robot to help out, but the idea of building something completely from scratch sounds like a bit of a headache? That's where turnkey solutions really shine. They're basically pre-packaged automation systems designed to get you up and running without all the fuss. Think of it like buying a flat-pack piece of furniture versus trying to build one from raw timber – one is much more straightforward.

Robotic Arms With Pre-Configured Software

These are a really popular choice. You get a robotic arm, but crucially, it comes with software already set up to handle specific jobs. So, instead of spending ages figuring out how to program it for, say, welding or picking up parts, the basic programming is already done. You might need to tweak a few settings to match your exact needs, but the heavy lifting is out of the way. It’s like getting a new appliance that’s already got its main functions programmed in.

Autonomous Mobile Robots For Logistics

If you've got a warehouse or a big factory floor, you've probably seen these zipping around. Autonomous Mobile Robots, or AMRs, are designed to move things from A to B all by themselves. They use fancy sensors and navigation tech to get around obstacles and find their way. The 'turnkey' part means they arrive ready to go – you don't need to lay down special tracks or do a load of complex setup. They just need to be told where to go and what to do, and off they trundle.

Integrated Systems For Specific Applications

These are the specialists. Instead of just a robot arm or a mobile base, you get a whole setup designed for one particular job. This could be a system for palletising boxes onto a truck, a packaging line that wraps products, or even a precise setup for placing tiny electronic components. The robot, grippers, sensors, and any other bits and bobs are all put together and tested to work perfectly for that one task. It’s automation as a complete package, ready to slot into your process.

When you're looking at these different types, remember that the 'turnkey' aspect means the system is designed to be as self-contained and ready-to-use as possible. The goal is to minimise the amount of custom engineering and integration work you, the end-user, have to do. It's all about getting you operational faster and with less hassle.

Turnkey Solutions Versus Customised Automation

So, you're looking at automating a process, and you've heard the terms 'turnkey' and 'customised'. What's the difference, and which one is right for you? It's a bit like choosing between buying a ready-made suit and having one tailored. Both can fit, but they serve different needs and come with different trade-offs.

Flexibility In Customisation

Customised automation is where you get exactly what you want, built from the ground up. If your production line has some really unusual steps, or you're working in a field with super strict rules, like aerospace or pharmaceuticals, then a bespoke system might be your only option. You get to design every little bit to fit your specific workflow, including any odd tools or peculiar setups. This level of control means the robot fits your process perfectly. However, this flexibility comes at a price. It takes more time, needs more technical know-how, and the initial outlay is usually higher. You're essentially paying for that perfect fit and the peace of mind that comes with meeting every single requirement.

When To Opt For A Turnkey Approach

On the flip side, turnkey solutions are all about speed and simplicity. Think of them as pre-packaged automation kits. They're designed for common tasks like palletising, welding, or just moving things around. If your needs are pretty standard, a turnkey system will likely do the job just fine, and it'll get you up and running much faster. You avoid the lengthy design and development phases. It's a bit like buying a good quality off-the-peg suit; it might not be exactly tailored, but it fits well enough and you can wear it straight away. For many small to medium-sized businesses that don't have a big engineering team, this is often the most practical route. You can get a reliable robotic automation system without needing to become experts yourselves.

Evaluating Your Specific Automation Needs

So, how do you decide? It really boils down to what you need to achieve and what resources you have. If you need something done quickly and cost-effectively for a common task, a turnkey solution is probably your best bet. It reduces risk and gets you seeing results sooner. But if your process is unique, or you have very specific compliance needs, then investing in a custom solution, despite the extra time and cost, might be the only way to go. It’s about balancing the need for speed and budget against the requirement for a perfect, bespoke fit.

Here's a quick rundown:

- Turnkey: Best for common tasks, faster deployment, lower initial risk, and simpler integration. Ideal if you have limited in-house engineering resources.

- Customised: Best for unique processes, highly specific requirements, or stringent compliance needs. Offers maximum flexibility but requires more time, budget, and technical input.

Ultimately, the choice between a turnkey and a customised automation solution hinges on a clear understanding of your operational goals, the complexity of the task at hand, and the resources you're willing to commit. Don't just jump at the first option; take the time to assess what will truly benefit your production in the long run.

Applications For Turnkey Robotic Solutions

When you're looking at automation manufacturing, it's easy to get lost in all the possibilities. But turnkey solutions really do simplify things, especially for specific jobs. They're basically pre-built systems designed to tackle particular tasks right out of the box. This means less fuss for you and faster results.

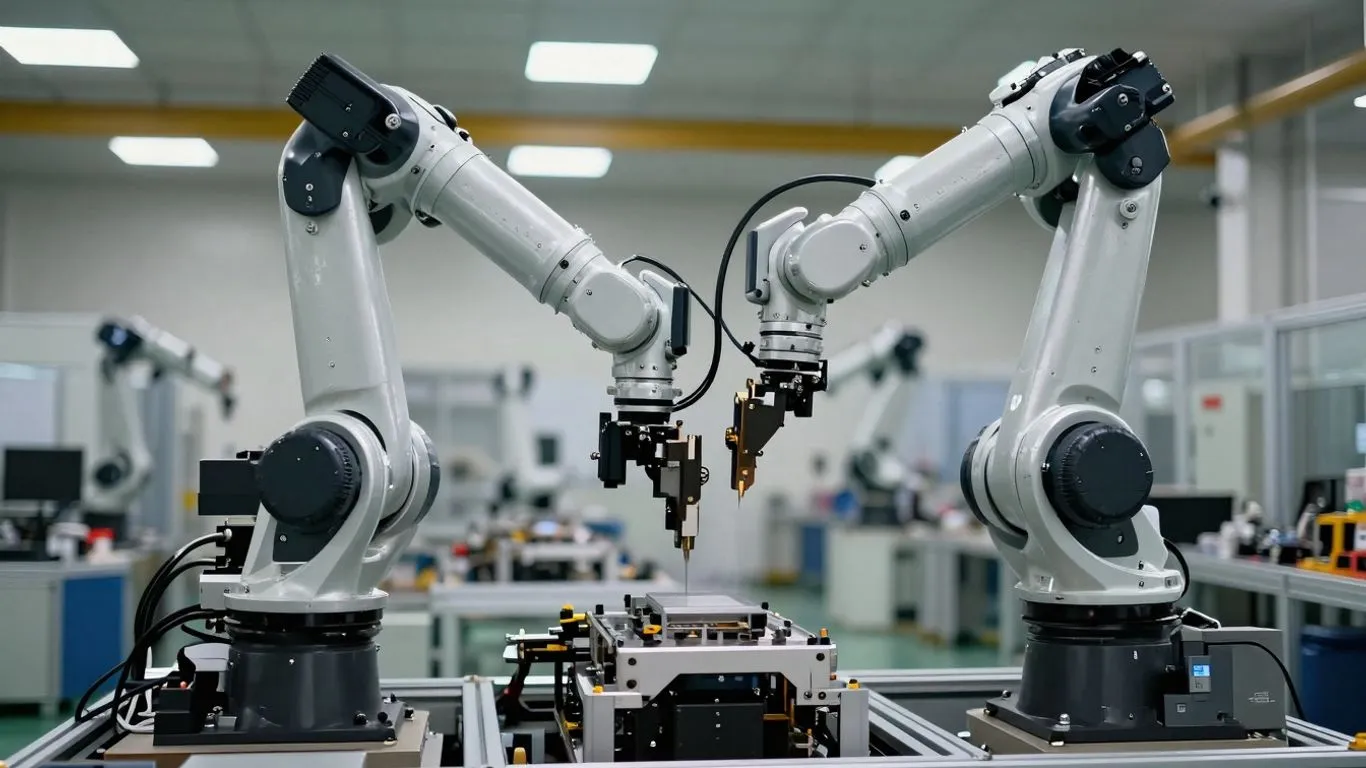

Streamlining Welding and Assembly

For tasks like Robot Metal Welding (TIG & MIG) & Ultrasonic Welding Solutions, a turnkey system is a game-changer. Instead of piecing together your own setup, you get a complete, tested unit. This ensures consistent weld quality, speeds up your production cycles, and cuts down on labour costs. Think about it: fewer errors, stronger joints, and more output. It's a big win for any manufacturing floor looking to improve these critical processes. These automated systems for manufacturing are designed for reliability.

Automating Palletising and Packaging

Packaging and palletising can be repetitive and physically demanding. Turnkey solutions here mean robots that can stack boxes or wrap pallets with precision and speed. They're programmed to handle different product sizes and weights, stacking them consistently every time. This not only saves on manual labour but also reduces damage to goods during transit. It’s about getting products out the door efficiently and safely.

Enhancing Material Handling Efficiency

Moving materials around a factory or warehouse is another area where turnkey robots shine. Autonomous Mobile Robots (AMRs), for instance, can navigate your facility, carrying parts or finished goods without needing fixed routes. This flexibility means you can adapt your workflow easily. They help keep production lines moving by ensuring parts are where they need to be, when they need to be there. It’s a smart way to keep things flowing.

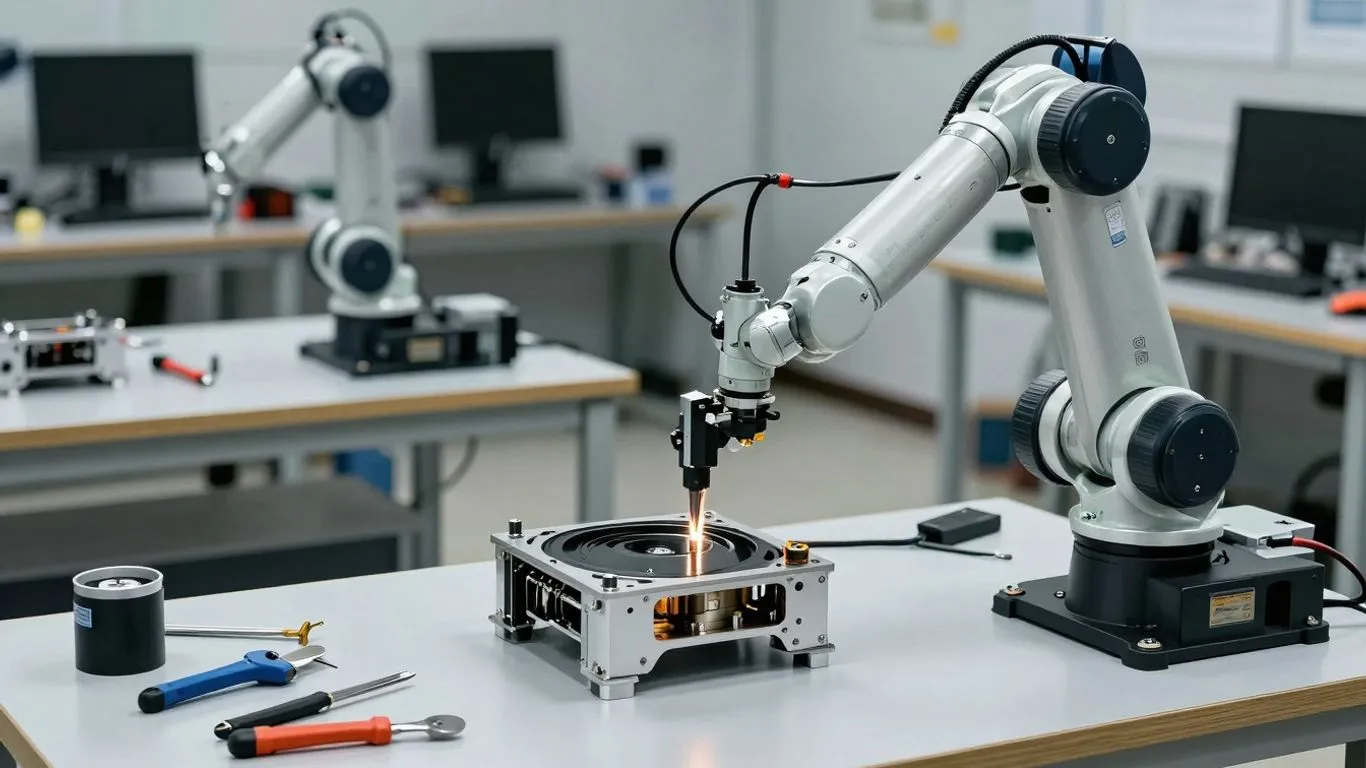

Precision Tasks In Electronics Manufacturing

In electronics, precision is everything. Turnkey solutions are often used for tasks like placing tiny components onto circuit boards or performing delicate soldering. These systems are built for high accuracy and repeatability, which is vital for producing reliable electronic devices. They can perform these intricate tasks faster and more consistently than manual methods, reducing defects and improving overall product quality. For businesses in this sector, getting this right is key to staying competitive.

Turnkey robotic solutions are particularly beneficial for small to medium-sized businesses that might not have extensive in-house engineering teams. They offer a straightforward path to automation without requiring deep technical knowledge to implement.

Here's a quick look at what you can expect:

- Welding & Assembly: Pre-configured robotic cells for consistent, high-speed production.

- Palletising & Packaging: Automated systems for efficient, error-free stacking and wrapping.

- Material Handling: Mobile robots for flexible and efficient movement of goods.

- Electronics: High-precision robots for delicate assembly and soldering tasks.

These systems are designed to integrate smoothly into your existing operations, providing a clear path to improved productivity and quality. If you're looking to upgrade your manufacturing processes, exploring these robotic automation solutions is a sensible next step.

Choosing The Right Turnkey Solution Provider

Right then, picking the right company to sort out your robotic turnkey solution is a bit like choosing a builder for your house. You want someone who knows their stuff, won't leave you with a half-finished mess, and actually understands what you're trying to achieve. It’s not just about the shiny robot; it’s about the whole package working for your specific needs.

Identifying Your Automation Objectives

Before you even start looking at providers, you've got to have a clear idea of what you want the robot to do. Are you trying to speed up packing boxes, make welding more consistent, or perhaps move materials around your warehouse more efficiently? Get specific. Think about the exact tasks, the materials involved, and the environment the robot will be working in. The clearer your objectives, the better a provider can match you with the right system. It’s no good asking for a solution to sort screws if you actually need to lift car engines.

Considering Budgetary And Time Constraints

Let's be honest, money and time are always factors. Turnkey solutions can vary a lot in price. A basic pick-and-place setup will cost less than a complex system for high-precision assembly. You need to figure out what you can realistically spend. Also, how quickly do you need this up and running? Turnkey systems are generally faster to deploy than custom builds, but some providers might have longer lead times than others. It’s worth asking about typical project timelines and what might affect them.

Ensuring Seamless System Compatibility

This is a big one. The new robotic system needs to play nicely with your existing equipment and software. You don't want to buy a solution only to find out it clashes with your current production line or IT infrastructure. Ask potential providers about their integration process. Do they offer support for connecting with your existing systems? What kind of testing do they do to make sure everything works together smoothly? A good provider will be upfront about any potential compatibility issues and how they plan to address them.

- Initial Consultation: Discuss your needs in detail. A good provider will listen more than they talk at this stage.

- System Design Review: Get a clear breakdown of the proposed solution, including hardware, software, and integration plans.

- Testing and Validation: Understand how they test the system before it's delivered to you.

- Post-Installation Support: Clarify what kind of support and training is included after the system is up and running.

- Less downtime: Get up and running quicker.

- Predictable outcomes: Know what to expect from your automation.

- Easier staff adoption: Your team can learn and use the system with less difficulty.

- Single point of contact: Often, you deal with one provider for the whole solution, simplifying support.

- Intuitive Interfaces: Often feature drag-and-drop functionality or clear visual menus.

- Pre-Configured Tasks: Common operations are already programmed and ready to go.

- Simplified Adjustments: Minor tweaks to parameters are usually straightforward.

- Reduced Training Needs: Staff can operate the system with less specialised knowledge.

Choosing the right provider means finding a partner who understands your business goals and can deliver a reliable, integrated solution that fits your operational reality. It's about more than just the hardware; it's about a complete, working system that adds real value.

The Value Proposition For Your Business

Reducing Engineering And Development Hours

When you opt for a turnkey robotic solution, you're essentially buying a pre-built system designed for a specific task. This means the heavy lifting – the custom programming, the intricate system design, and the initial testing – has already been done by the provider. For your business, this translates directly into significantly fewer engineering hours spent on development. Instead of reinventing the wheel for each automation project, you can deploy a proven solution. This frees up your internal engineering teams to focus on other critical areas, like process improvement or developing entirely new product lines, rather than getting bogged down in repetitive integration work.

Building Enhanced Reliability Over Time

One of the most compelling aspects of turnkey systems is their inherent reliability, which actually improves with each deployment. Because these solutions are pre-engineered and tested for a particular application, any initial 'teething troubles' are ironed out during the development phase. When you deploy the same turnkey solution multiple times, you're not dealing with a brand-new, untested system each time. Instead, you're implementing a solution that has already proven its mettle. This consistent performance builds confidence and positions your business as a dependable partner, knowing that the automation you provide will work as expected, time after time.

Scalability Through Repeatable Deployments

Turnkey solutions are built with scalability in mind, making it straightforward for your clients to expand their automation capabilities. Once a client has successfully implemented their first turnkey robotic cell, they can easily replicate that success. The process becomes akin to a 'copy and paste' operation. Need more capacity? Simply deploy another identical cell. This repeatable deployment model allows for rapid scaling of automation without the need for extensive re-engineering or customisation for each new unit. It’s a streamlined approach that supports business growth efficiently.

The core idea here is that you're moving from a service-based model, where each project is a unique undertaking, to a product-based model. You develop a robust, pre-configured solution once, and then you can sell and deploy it multiple times. This not only speeds up your sales cycle but also allows you to build a catalog of reliable automation products, rather than just custom integration services.

Client Advantages With Turnkey Robotic Systems

So, you're thinking about bringing robots into your operation, but the whole customisation thing feels a bit daunting? That's where turnkey robotic systems really shine for businesses like yours. They're designed to make your life easier, cutting down on hassle and getting you up and running faster.

Faster Return On Investment

One of the biggest draws is how quickly you can start seeing a return on your investment. Because these systems are pre-built and tested, the time it takes to get them installed and working is significantly shorter than with a fully bespoke setup. Less time spent on installation and fine-tuning means your production lines can start benefiting from automation sooner.

Reduced Operational Risk

With a turnkey solution, a lot of the guesswork is already done. The system has been developed and refined, meaning the kinks have been ironed out before it even arrives at your facility. This predictability translates into a much lower risk of unexpected problems cropping up once the system is live. You're not really experimenting; you're implementing a proven solution.

Consistent Performance and Reliability

Because these systems are standardised, they tend to perform consistently, time after time. You know what you're getting, and you can rely on that performance. This consistency is a huge win for maintaining production quality and meeting output targets without the usual headaches that can come with new, unproven automation.

Simplified Deployment and Training

Forget about needing a team of robotics engineers on-site for weeks. Turnkey systems are built for straightforward integration. They often come with user-friendly interfaces and pre-programmed functions, making them easier for your existing staff to operate and maintain. Training is usually more streamlined, too, meaning your team can get up to speed without extensive, specialised courses.

Here's a quick look at what that means for you:

The Role Of Software In Turnkey Solutions

Programming Software For Turnkey Applications

When you get a turnkey robotic system, a big part of what makes it "turnkey" is the software. It's not just about the robot arm or the conveyor belt; it's how all the bits and pieces talk to each other. The programming software is the brain of the operation. For these ready-to-go systems, the software is usually pre-configured for specific tasks. Think of it like buying a new computer – it comes with an operating system already installed, ready for you to start using. With robotics, this means the software is designed to handle common jobs like picking and placing, welding, or palletising without you needing to be a coding wizard. This makes it much simpler to get started, and you can often find software that allows for easy adjustments if your needs change slightly. It's all about making the complex stuff feel straightforward.

Simulation And Testing For Reliability

Before a turnkey system even gets to your factory floor, a lot of work goes into making sure it actually works. This is where simulation and testing come in. Developers use special software to create a virtual model of the robot and its environment. They can then run through all sorts of scenarios – what happens if a part is slightly out of place? What if the conveyor belt speeds up? By testing these things in a simulation, they can iron out any potential problems before they become real-world issues. This thorough testing is a big reason why turnkey solutions are generally quite reliable right out of the box. It means less downtime and fewer surprises when you start using the system for real. It’s a bit like test-driving a car extensively before you buy it, just in a digital world.

Ease Of Use For End-Users

One of the main selling points of a turnkey solution is that it's meant to be easy to use, even if you don't have a team of robotics engineers on staff. The software is often designed with the end-user in mind. This can mean graphical interfaces that are intuitive, or pre-set programs that you can select and run with minimal input. For example, if you need a robot to stack boxes, you might just select a "palletising" program and input the dimensions of your boxes. The system then figures out the best way to stack them. This focus on simplicity means that your own staff can get up to speed quickly, reducing the need for extensive, costly training. It’s about making automation accessible, not just for big corporations, but for businesses of all sizes looking to improve their processes. This approach helps businesses integrate advanced automation without needing deep technical knowledge, making it a practical choice for many. You can find more information on how industrial automation is changing manufacturing on this page.

Ease Of Use For End-Users

One of the main selling points of a turnkey solution is that it's meant to be easy to use, even if you don't have a team of robotics engineers on staff. The software is often designed with the end-user in mind. This can mean graphical interfaces that are intuitive, or pre-set programs that you can select and run with minimal input. For example, if you need a robot to stack boxes, you might just select a "palletising" program and input the dimensions of your boxes. The system then figures out the best way to stack them. This focus on simplicity means that your own staff can get up to speed quickly, reducing the need for extensive, costly training. It’s about making automation accessible, not just for big corporations, but for businesses of all sizes looking to improve their processes. This approach helps businesses integrate advanced automation without needing deep technical knowledge, making it a practical choice for many. You can find more information on how industrial automation is changing manufacturing on this page.

The software component of a turnkey robotic system is designed to abstract away the complexities of programming and control. The goal is to provide a functional, ready-to-deploy solution where the user interacts with the system through a simplified interface, focusing on the task rather than the underlying code. This makes automation more accessible and quicker to implement for a wider range of businesses.

Wrapping Up

So, there you have it. Turnkey robot solutions really do make automation a lot more straightforward. Instead of wrestling with complicated setups, you get something that’s pretty much ready to go. It means less fuss, faster results, and usually, a smoother ride overall. While they might seem like a bit of an upfront investment, the time saved, fewer mistakes, and less downtime often make them a smart choice in the long run. Just think about what you need to get done, what you can spend, and make sure it fits with what you already have. It’s about getting your automation sorted without all the usual headaches.