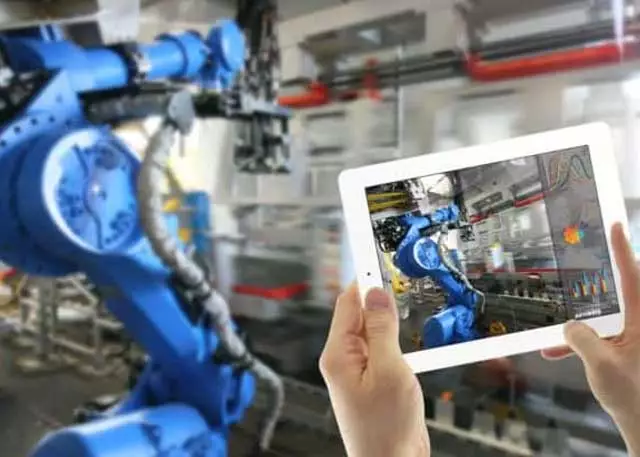

Automotive Industry

With the advent of robotic arms, processes such as welding, painting, material handling and quality inspection are automated. It helps a company to save costs and speed up the product’s turnaround time.

- Robotic MIG, TIG & Spot welding

- Assembly Line Automation

- Robotic Drilling & Milling

- Machine Tending

- Vision Inspection Testing

- Material Handling & Traceability

Electronic Industry

Precision and the compactness of every component matter in the electronic industry. It is impossible to meet the volume demanded by the market through manual labor. This increasing cost pressure has forced manufacturers to switch to alternatives that increase output. In this case, robotic manufacturing.

- Robotic Pick & Place

- Robotic Screwing Solution

- Conveyor & Assembly Line Solution

- Robotic Gluing / Soldering / Potting

- PCB Assembly & Sorting Machine

- Auto Labeling

Electrical Industry

The electrical industry is constantly trying to optimize the efficiency of every workstation. Robotic automation solution ensures consistency in the output and also increases safety.

- Pick And Place

- Coil winding & Resistance welding

- Measurement & inspection

- Vision Systems

- Robotic Handling

- Palletising

FMCG Industry

With the increase in government regulations, FMCG companies are deploying robotic automation to improve the quality and production speed. The robust features such as anti-corrosive surfaces and tight seals that resist contamination help the food industry raise its sanitary standards. Manufacturers prefer this solution for its cost-effectiveness, low footprint, and higher throughput rates.

- Packing Solution

- Sorting & Tracking

- Robotic End Of Line Palletizing / De Palletizing

- Conveyor Solution

- Case Erector

Medical Industry

Robotic technology ensures aseptic conditions since filling, kitting, and assembly processes are automated. It allows the pharma company to achieve productivity, cost-efficiency, and flexibility.

- Case Packing

- Line Palletizing / De Palletizing

- Conveyor Solution

- Case Erector

Aerospace Industry

Robotic solutions are capable of detecting minute variations in the patency, thickness, and integrity of aircraft skins and foils. They can perform repetitive and sensitive tasks like riveting, interior & exterior welding, assembly process, and bolting with precision.