>

>

The landscape of Fast Moving Consumer Goods (FMCG) has undergone significant changes compared to the past decade. The preferences of consumers have shifted, leading to changes in demand and supply chain patterns. With the adoption of automation in various industries, the FMCG sector has become more digitised.

The FMCG sector in Master linque automation plays a crucial role in driving economic growth in India. As per the research division of Statista, it is the fourth largest sector in the Indian economy in terms of accounting calculation.

A number of large companies like P&G, Hindustan Unilever, Gillette, Coca cola, and many more have adopted automation. Because Robots are performing incredible jobs compared to human based work, they can perform many jobs from palletising, mixing, cutting, pasting to quality checking.From 1950 to 1980, the FMCG sector in India had limited investment and local people had lower purchasing power, resulting in a preference for necessity products over premium ones. The Indian government supported local retailers. However, between 1980 and 1990, demand for a wider variety of products increased, leading to growth in the FMCG industry and competition from other companies. The media industry also saw growth during this time, providing further incentive for companies to increase profitability. After globalisation and liberalisation in 1991, foreign FMCG companies were encouraged to enter India, leading to increased brand awareness and government intervention to support their operations.

Are you searching for the top/best automated manufacturing company in Chennai, Hosur, Bangalore, Coimbatore, and Trichy? Look no further than Master Linque Automation - one of the Top Special purpose machine manufacturing in Chennai.

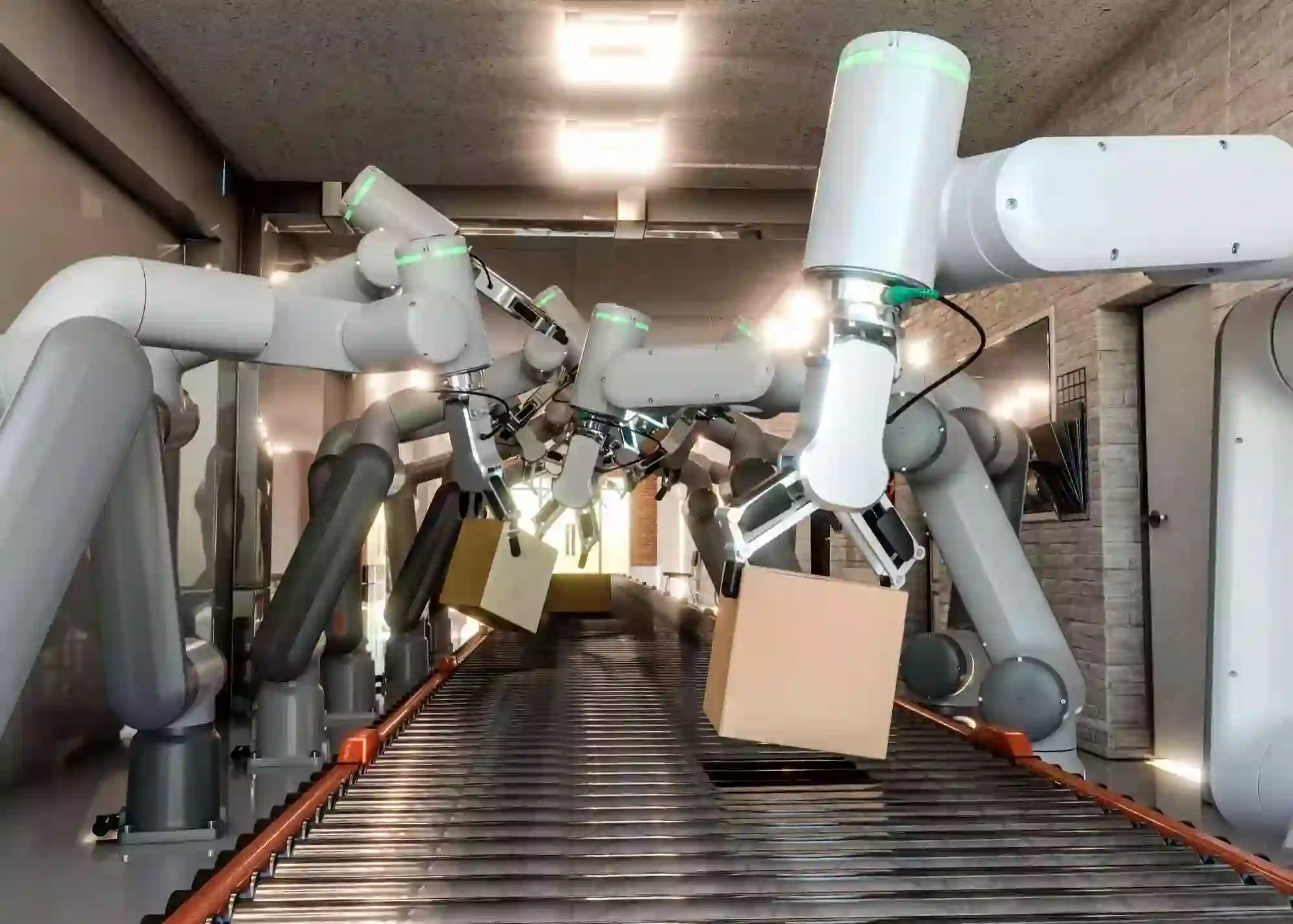

Over the last few years, cobot deployment has surged across the globe in the automation industry. The pandemic caused significant disruptions to the supply chain and greatly impacted the manufacturing industry. As a result, businesses faced pressure to enhance and optimise their operations to meet production demands and maintain competitiveness in the market. The adoption of robotics and automation in the industry has aided manufacturers in achieving business resilience. The FMCG industry faces several challenges, including reduced labour efficiency in mundane and repetitive tasks such as packaging, palletizing, logistics, warehousing, and weightlifting. However, the application of robotics automation in Chennai has made these activities efficient and straightforward. The FMCG sector employs robotics and automation in various ways, including:

1. The packaging and palletising processes are known for their non-ergonomic tasks, which often lead to repetitive strain injuries and musculoskeletal disorders among workers. These tasks involve lifting heavy loads and bending to pick up or wrap goods, which not only carry the risk of injury but also increase the likelihood of human error due to reduced attention spans. Cobots, programmed to work on repetitive tasks, have been introduced to relieve workers from performing tedious and mundane tasks. By taking on these tasks, cobots increase the production rate on the factory floor and decrease fatigue in workers, allowing them to focus on higher-value tasks

2. Over the past few years, robotics has seen a significant increase in adoption in the warehousing and logistics industry. Cobots are ideal for this industry as they are lightweight, flexible, and able to transfer goods consistently and quickly without the need for significant infrastructure changes. This has relieved workers of strenuous tasks, increased production, and reduced the cost of production.

3. Inventory control is a rigorous process, especially in retail where maintaining stock is a necessity. Automation has made inventory more transparent and eliminated the risk of last-minute supply outages. Cobots equipped with sensors allow manufacturers to scan inventory and identify the space required for the storage of goods, creating a more efficient space and eliminating the risk of breakage or wastage. Manufacturers are relying on cobots more than ever before due to their precision and consistent capabilities, allowing them to make better decisions.

4. Maintaining quality and keeping checks on ingredients is crucial in the FMCG industry. Repetitive actions can lead to an increase in human errors, which can lead to product and materials wastage. Cobots are taking on ergonomically challenging tasks, freeing human employees to work on better tasks. This has increased efficiency and productivity while reducing the prevalence of human errors.

5. The FMCG is the top SPM Manufacturing in Chennai and its sector heavily depends on seasonal demand and constant changes in consumer tastes and environments. Cobots are flexible and can be redeployed to perform various tasks without the need for professional engineers, unlike traditional industrial robots. Robotics and automation have defied barriers caused by the global pandemic and escalating conflicts, delivering new options for commercial growth, sustainability monitoring, and operational efficiency. Cobots have been a game-changer in this growing industry, allowing for the perfect man-machine collaboration. The future of the FMCG sector is exciting, with Automated manufacturing companies and Robotic Automation in Chennai opening up opportunities for growth and efficiency.

In comparison with other companies, the Master Linque Automation is a best Automated Manufacturing company in Chennai, harnessing technology to provide cutting-edge automation products and services. Our extensive expertise includes Special Purpose Machine Manufacturing in Chennai, and we offer an array of products, such as Industrial Automation, Precision Jigs & Fixtures, Assembly and Industrial Robotic solutions, Welding solutions, Testing & Inspection solutions, Automated Material Handling Solutions, and more. Our products and services cater to diverse industries, such as Automotive, Electrical, Electronic, Medical, Aerospace, and FMCG. As providers of Industrial Turnkey Automation Solutions, we are devoted to providing our customers with high-quality products, services, and solutions.

Urban and Rural Area Trends in FMCG:

The trends in the FMCG automation industry differ between urban and rural areas. In urban areas, there is a higher demand for automation due to higher labour costs and a need for faster production and delivery. Automation technologies such as robotics and artificial intelligence are being increasingly adopted in urban FMCG industries. In contrast, rural areas may have lower levels of infrastructure and technology adoption, leading to a slower pace of automation adoption in FMCG industries. However, Master linque automation is the increasing availability of technology for all industries and now the government initiatives to improve rural infrastructure, the automation trend is gradually expanding to rural areas as well.

Urban and Rural Area Trends in FMCG:

The trends in the FMCG automation industry differ between urban and rural areas. In urban areas, there is a higher demand for automation due to higher labour costs and a need for faster production and delivery. Automation technologies such as robotics and artificial intelligence are being increasingly adopted in urban FMCG industries. In contrast, rural areas may have lower levels of infrastructure and technology adoption, leading to a slower pace of automation adoption in FMCG industries. However, Master linque automation is the increasing availability of technology for all industries and now the government initiatives to improve rural infrastructure, the automation trend is gradually expanding to rural areas as well.

Usage of Automation in FMCG:

Automation is increasingly being used in the fast-moving consumer goods (FMCG) industry to improve efficiency, reduce costs, and enhance product quality. Some of the common uses of automation in FMCG include:

Production line automation: Automation is used to streamline the manufacturing process, increase output, and reduce errors. This involves the use of robots, automated assembly lines, and packaging machines.

Inventory management: Automation is used to track inventory levels, forecast demand, and manage supply chains. This involves the use of software systems that automate the procurement, storage, and distribution of goods.

Quality control: Automation is used to ensure the quality of products. This involves the use of sensors, cameras, and other monitoring devices to detect defects and ensure that products meet certain standards.

Distribution and logistics: Automation is used to optimise distribution and logistics operations. This involves the use of software systems that automate order processing, transportation planning, and warehouse management.

Customer service: Automation is used to improve customer service by providing self-service options, such as online ordering, automated phone systems, and chatbots.

Overall, the use of Robotic Automation in FMCG can improve efficiency, reduce costs, enhance product quality, and improve customer satisfaction.

Advantages and Improvement of Automation in FMCG Industry

Here we share several Advantages and Improvements that automation can bring to the FMCG industry:

Increased Productivity: Automation can significantly increase productivity in the FMCG industry by reducing the time required for tasks, increasing the speed of production, and minimising errors.

Cost Savings: Automation can help reduce labour costs, energy costs, and material waste, which can lead to significant cost savings for FMCG companies.

Improved Quality: Automation can help improve the quality of products by reducing errors, ensuring consistency, and detecting defects more quickly.

Better inventory management: Automation can help optimize inventory management by tracking inventory levels, forecasting demand, and ensuring that products are delivered on time.

Enhanced Safety: Automation can help improve safety in the FMCG industry by reducing the risk of accidents and injuries caused by human error.

Increased Flexibility: Automation can help FMCG companies adapt to changing market conditions by enabling them to quickly adjust production levels and product offerings.

Better Customer Service: Automation can improve customer service by providing faster and more accurate order processing, better product tracking, and more personalised service.

Overall, the use of automation in the FMCG industry can lead to improved efficiency, cost savings, better quality, and better customer service, which can help companies gain a competitive advantage in the market.

In conclusion, automation has become increasingly important in the fast-moving consumer goods (FMCG) industry as companies seek to improve efficiency, reduce costs, enhance product quality, and improve customer satisfaction. Automation has a wide range of applications in FMCG, including production line automation, inventory management, quality control, distribution and logistics, and customer service. The benefits of automation in FMCG are significant, including increased productivity, cost savings, improved quality, enhanced safety, increased flexibility, and better customer service. As the FMCG industry continues to evolve, the use of automation is likely to become even more important in driving innovation and growth.