Automation has revolutionized the manufacturing industry, bringing numerous benefits and transforming the way things are produced.

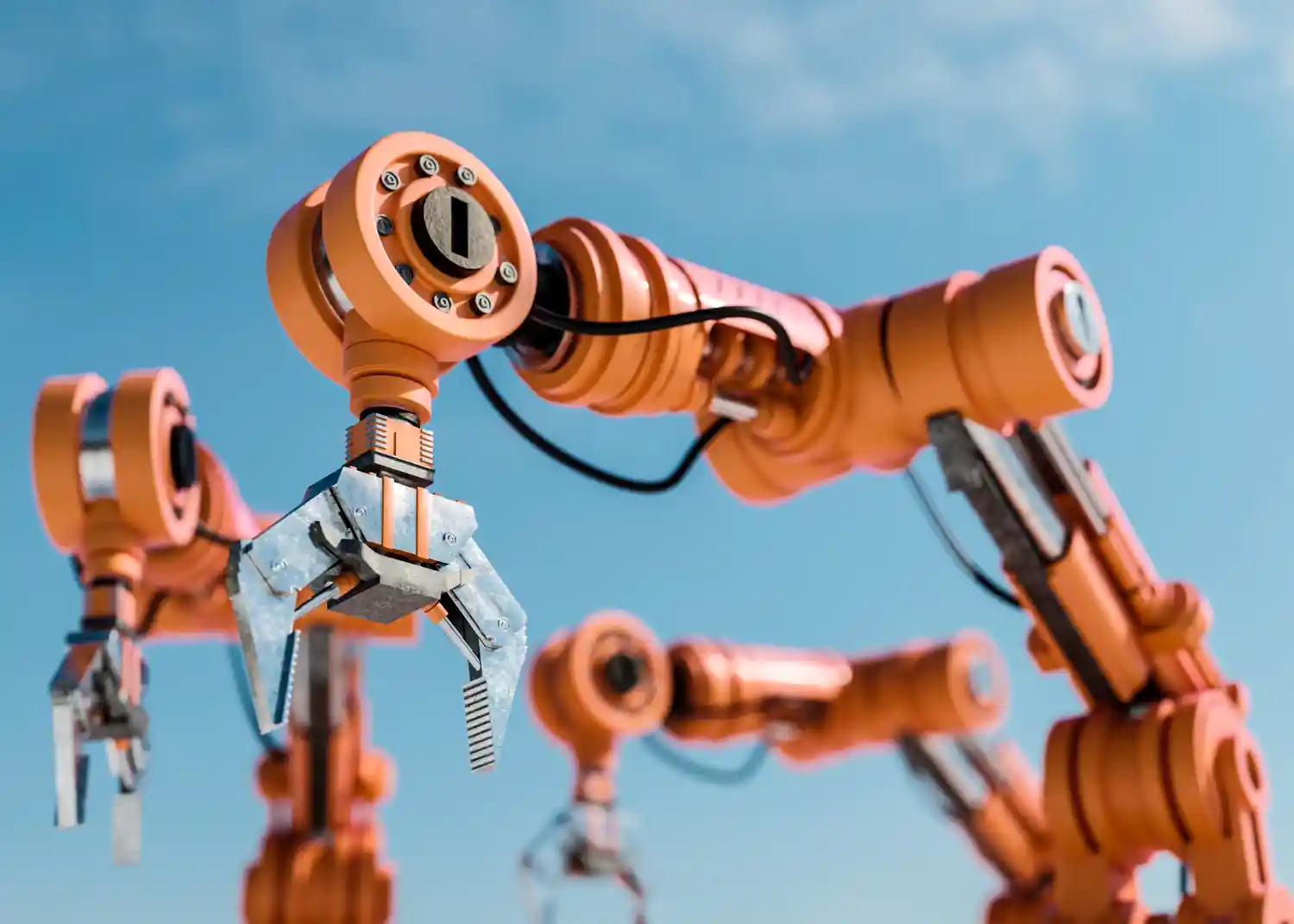

Automation has revolutionized the manufacturing industry, bringing numerous benefits and transforming the way things are produced. By leveraging advanced technologies and robotics, automation has significantly improved efficiency, productivity, and quality in manufacturing processes. In this article, we will explore the pros of automation in the manufacturing industry, highlighting the advantages it offers to businesses. So let's delve into the world of automation and discover how it has become a game-changer for manufacturers.

Introduction : The Role of Automation in Manufacturing

Automation in the manufacturing industry involves the use of advanced machinery, robotics, and computer systems to perform various tasks traditionally carried out by humans. It aims to streamline production processes, increase efficiency, and reduce manual labor. With the advancements in technology, automation has become an integral part of modern manufacturing, allowing businesses to stay competitive in today's fast-paced market.

Increased Efficiency and Productivity

One of the primary benefits of automation in the manufacturing industry is the significant increase in efficiency and productivity. Automated systems can perform tasks faster and with higher precision than humans, leading to shorter production cycles and higher output levels. By eliminating human error and reducing downtime, manufacturers can optimize their operations and achieve higher overall productivity.

Enhanced Quality and Consistency

Automation plays a crucial role in ensuring product quality and consistency. Machines and robots can perform tasks with consistent precision, reducing the risk of errors and defects. By adhering to predefined parameters, automated systems can maintain a high level of quality throughout the manufacturing process. This consistency is particularly important in industries where precision and accuracy are critical, such as aerospace, automotive, and electronics.

Cost Reduction and Improved ROI

Implementing automation in the manufacturing industry can result in significant cost reductions and improved return on investment (ROI). While the initial investment in automated systems may be substantial, the long-term benefits outweigh the costs. Automation in the manufacturing industry leads to cost savings by reducing labor expenses, minimizing material waste, and optimizing energy consumption.. By streamlining operations and improving overall efficiency, manufacturers can achieve cost savings and realize a higher ROI.

Greater Safety for Workers

Automation offers improved safety conditions for workers in the manufacturing industry. By replacing humans in hazardous or physically demanding tasks, automation minimizes the risk of accidents and injuries. Robots and machines can handle tasks involving heavy lifting, repetitive motions, or exposure to harmful substances, protecting workers from potential harm. This allows manufacturers to create a safer working environment while ensuring the well-being of their employees.

Streamlined Supply Chain and Logistics

Automation has a significant impact on the supply chain and logistics processes in the manufacturing industry. Automated systems enable real-time tracking of inventory, efficient material handling, and streamlined logistics operations. By integrating automated solutions with inventory management software, manufacturers can optimize their supply chain, reduce lead times, and enhance overall efficiency in delivering products to customers.

Flexibility and Customization

Automation in Chennai offers manufacturers the ability to achieve greater flexibility and customization in their production processes. Advanced robotic systems can quickly switch between different tasks and adapt to changing production requirements. This flexibility allows manufacturers to respond to market demands more efficiently and offer customized products tailored to specific customer needs. By leveraging automation, manufacturers can stay agile and meet the ever-changing demands of the industry.

Faster Time-to-Market

With automation, manufacturers can significantly reduce the time it takes to bring a product to market. Automated systems can accelerate production cycles, eliminate bottlenecks, and streamline workflows. By automating repetitive and time-consuming tasks, manufacturers can optimize their processes and shorten the overall product development and manufacturing timeline. This enables them to respond quickly to market trends and gain a competitive edge.

Improved Data Collection and Analysis

Automation provides manufacturers with valuable insights through improved data collection and analysis. Automated systems can collect real-time data on production metrics, quality control parameters, and equipment performance. This data can be analyzed to identify areas for improvement, optimize processes, and make data-driven decisions. By leveraging automation and data analytics, manufacturers can enhance their operational efficiency and drive continuous improvement.

Competitive Advantage

Implementing automation in the manufacturing industry can provide a significant competitive advantage. Automated systems enable manufacturers to produce high-quality products more efficiently, giving them an edge over competitors. By reducing costs, improving productivity, and enhancing customer satisfaction through faster delivery and customization options, businesses can position themselves as industry leaders. Automation empowers manufacturers to stay ahead in the market and meet the evolving demands of customers.

Environmental Sustainability

Automation machine manufacturers in chennai also contributes to environmental sustainability. By optimizing energy consumption, reducing material waste, and improving process efficiency, automation helps minimize the environmental impact of manufacturing operations. Automated systems can be designed to operate with maximum energy efficiency and incorporate sustainable practices. By embracing automation, manufacturers can align their operations with environmental conservation goals and contribute to a greener future.

Training and Skill Development

The implementation of automation in the manufacturing industry necessitates a shift in the skill requirements for workers. As manual tasks are replaced by automated systems, there is a need for employees to develop new skills related to operating and maintaining the machinery. Manufacturers can invest in training programs to upskill their workforce and ensure a smooth transition to automated processes. This investment in training and skill development not only benefits the employees but also strengthens the company's capabilities in the long run.

Integration with Artificial Intelligence (AI)

Automation in the manufacturing industry is increasingly being integrated with artificial intelligence (AI) technologies. AI-powered automation systems can learn from data, make autonomous decisions, and continuously optimize manufacturing processes. By combining automation with AI, manufacturers can achieve higher levels of efficiency, predictive maintenance, and adaptive production. This integration opens up new possibilities for advanced manufacturing and drives innovation in the industry, robotic automation in chennai

Challenges of Implementing Automation

While automation brings numerous benefits, its implementation in the manufacturing industry also poses challenges. Some of the key challenges include the high initial investment, integration complexities, potential job displacement, and the need for workforce upskilling. It is essential for manufacturers to carefully plan and strategize their automation initiatives, considering these challenges and implementing them in a phased and structured manner. special purpose machine manufacturers in chennai