In Chennai, there are several top automation manufacturing company that specialize in industrial automation and machine manufacturing. These companies are known for their expertise in developing and implementing automation processes to enhance productivity and efficiency in manufacturing operations. They utilize advanced technologies, such as robotics and special purpose machines (SPMs), to automate various stages of the manufacturing process. Let's explore the key steps involved in the automation process of machine manufacturing:

Automation in Chennai has witnessed tremendous growth in recent years, establishing the city as a prominent hub for industrial manufacturing and automation. With the presence of several top automation manufacturing company, Chennai offers a diverse range of automation solutions tailored to meet the needs of various industries. These companies are recognized as the best in the field, consistently delivering cutting-edge technology and innovative automation systems. Chennai's reputation as the best industrial manufacturing city is further strengthened by the presence of these top automation manufacturing companies, which combine their expertise with state-of-the-art facilities and a skilled workforce to provide unmatched automation solutions. Whether it's optimizing production processes, improving efficiency, or enhancing product quality, Chennai's top automation manufacturing company are leading the way in transforming the industrial landscape with their exceptional automation capabilities.

Planning and Analysis: The automation journey begins with a thorough analysis of the manufacturing process. Experts from the automation company assess the existing workflow, identify areas that can be automated, and determine the specific requirements and goals of the client. This stage helps in understanding the challenges and opportunities for automation.

Design and Engineering: Once the analysis is complete, the automation company's team collaborates with the client to design an optimal automation solution. This involves creating detailed engineering drawings, selecting appropriate automation components, and developing a comprehensive plan for integrating automation into the manufacturing process.

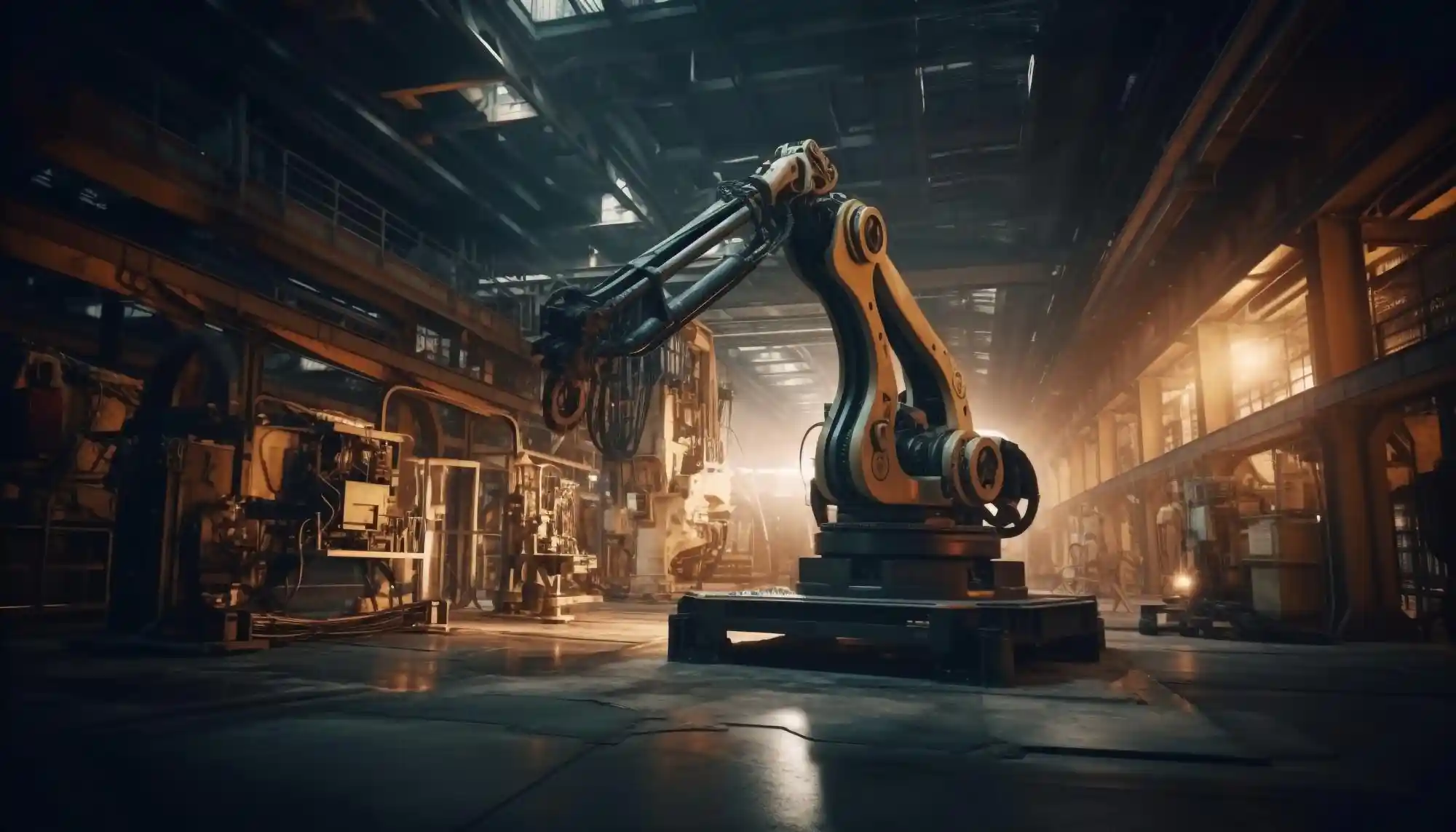

Component Selection and Integration: In this stage, the automation company procures the necessary components and equipment required for automation. This may include robotic arms, conveyor systems, sensors, actuators, and other specialized machinery. The integration process involves seamlessly incorporating these components into the existing manufacturing setup.

Programming and Control Systems: Automation systems require sophisticated programming to perform tasks accurately and efficiently. Skilled engineers program the automation equipment and develop control systems that coordinate the operation of different machines and devices. They ensure smooth communication and synchronization between various components, enabling seamless automation.

Testing and Validation: Before full-scale implementation, the automation solution undergoes rigorous testing and validation. This stage involves running simulations and conducting real-world tests to ensure that the automation process meets the desired objectives. Any issues or inefficiencies are identified and resolved during this phase.

Implementation and Training: Once the automation system is thoroughly tested and validated, it is implemented in the manufacturing facility. The automation company's experts work closely with the client's team to deploy the automation solution and provide training on its operation and maintenance. Training ensures that the client's personnel are familiar with the technology and can effectively utilize it.

Monitoring and Maintenance: After implementation, the automation system is monitored to ensure its smooth operation. Regular maintenance and preventive checks are conducted to keep the equipment in optimal condition. The automation company may offer ongoing support services to address any technical issues and optimize the performance of the automation solution.