Hello and welcome! Today, we're going to discuss a fascinating topic that is revolutionising the manufacturing industry: automation in special purpose machine manufacturing. As technology advances, more and more companies are turning to automation to increase efficiency, productivity, and reduce costs. With automation, special purpose machines can now perform complex tasks with speed and precision, which were previously impossible or highly challenging. Join Master linque automation, as we explore the benefits, challenges, and future prospects of automation in the special purpose machine manufacturing company in Chennai, Hosur, Bangalore, coimbatore, Trichy. Compared to other manufacturing industries master linque automation is the Top Automation Manufacturing company in chennai.

What is the Special Purpose Machine Manufacturing Industry?

The Special Purpose Machine (SPM) manufacturing industry is a niche sector that specialises in producing machines that are designed for specific tasks or functions. These machines are customised to meet the unique requirements of a particular application or process. Unlike general-purpose machines, which can perform a wide range of tasks, SPMs are engineered to perform a specific operation or set of operations with high precision and accuracy. In our industries we provide best in class automation services because we are providing the Industrial Turnkey Automation Solutions to everyone. As a Robotic Automation in Chennai, we are the best Manufacturing automation company in Chennai, Hosur, Bangalore, coimbatore, Trichy.

Revolution in SPM Manufacturing Industry

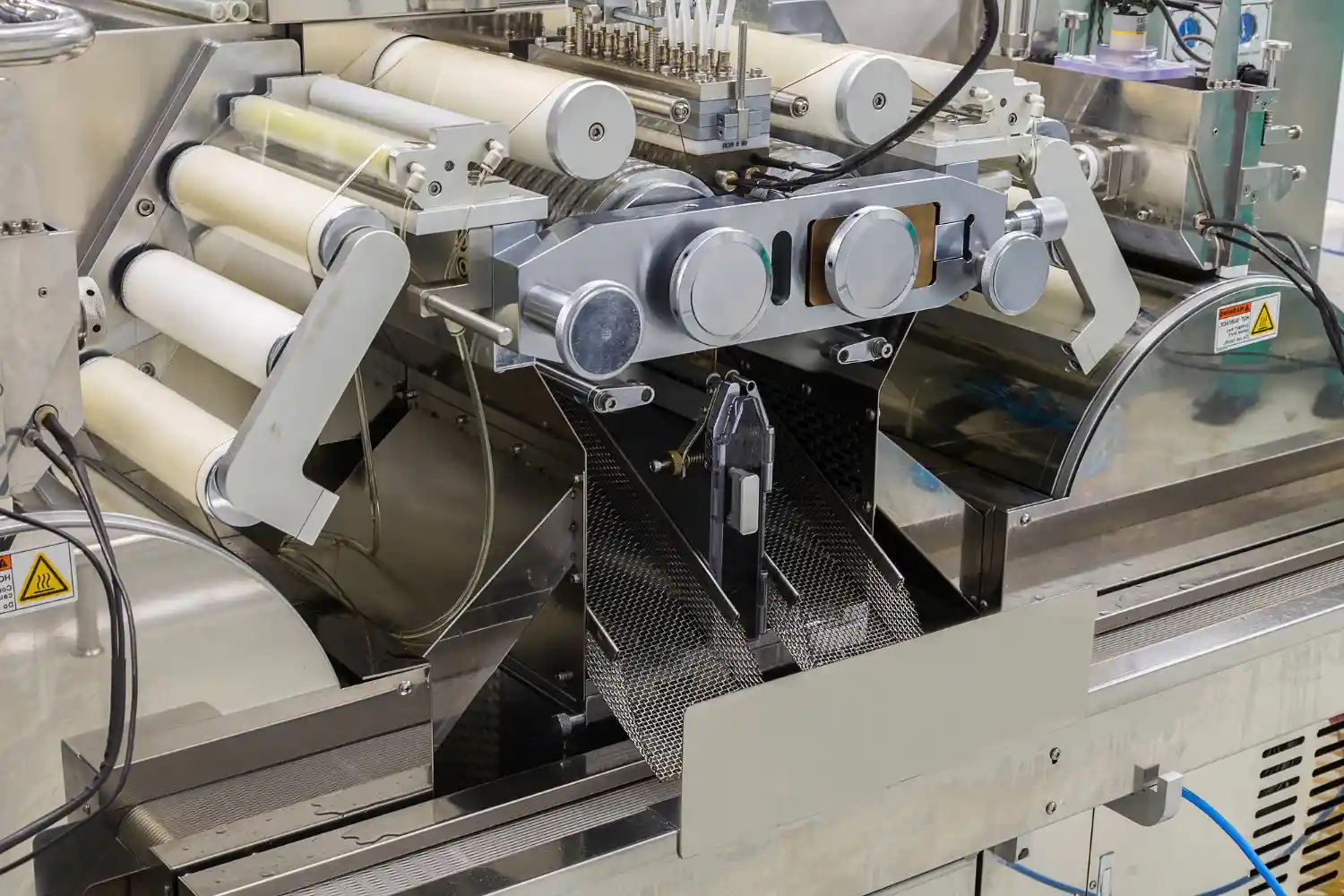

Automation has revolutionised the manufacturing industry in recent years, particularly in the special purpose machine manufacturing sector. Special purpose machines are custom-built machines that are designed to perform specific tasks in a manufacturing process. These machines are used in a variety of industries such as automotive, aerospace, and pharmaceuticals. With the advancements in technology, automation has become an integral part of special purpose machine manufacturing. Wanna know more details about revolution of SPM manufacturing in FMCG automotive industry http://www.masterlinqueautomation.com/revolution-of-fmcg.php

Automation in special purpose machine manufacturing refers to the use of various technologies such as robotics, computer-aided design (CAD), and computer-aided manufacturing (CAM) to automate the manufacturing process. Automation has numerous benefits in this industry, including increased productivity, improved quality, reduced costs, and enhanced safety.

How Automation works in SPM Manufacturing Industry

Automation plays a significant role in the Special Purpose Machine (SPM) manufacturing industry by increasing efficiency, reducing human error, and improving overall productivity. Automation in SPM manufacturing can be achieved through various technologies, including robotics, programmable logic controllers (PLCs), and computer numerical control (CNC) systems. Here we explain in detail about the top 10 automation industries companies in chennai click here http://www.masterlinqueautomation.com/top-10-automated-manufacturing-company-in-chennai.php

Robotic automation is commonly used in SPM manufacturing for tasks such as material handling, assembly, and inspection. Robots are programmed to perform specific tasks with high precision and accuracy, reducing the need for human intervention and minimising errors.

PLCs and CNC systems are used to automate the operation of SPMs. PLCs are microprocessors that control the operation of a machine by executing a series of programmed instructions. They are commonly used to control the motion, speed, and positioning of the machine.

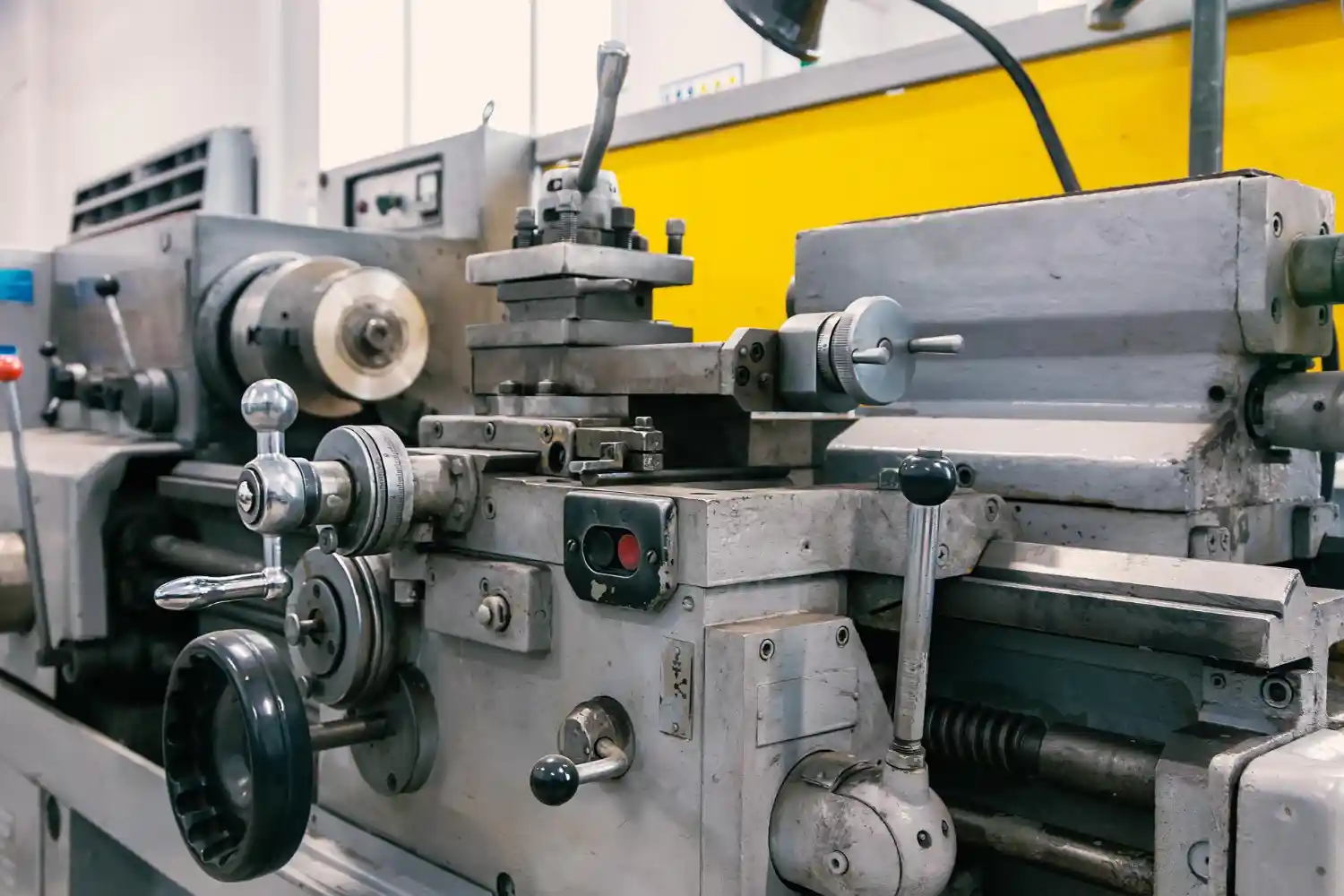

CNC systems, on the other hand, are used to automate the manufacturing process by controlling the movement of the machine tool, such as a cutting or milling machine. The CNC system reads instructions from a computer program and translates them into precise movements of the machine tool, resulting in highly accurate and consistent production.

Benefits of Automation in SPM Manufacturing

One of the main benefits of automation in special purpose machine manufacturing is increased productivity. Automated machines can work continuously without breaks, which means that they can produce more output in a shorter period of time. This is particularly useful in industries where large volumes of products need to be manufactured quickly and efficiently. As a Top and best automation manufacturing industry in Chennai, master linque automation provides best manufacturing solutions to particular industries like Automotive industry, Electronic industry, Electrical industry, FMCG industry, Medical industry, and Aerospace industry. Click here to know more detail and information about master linque automation http://www.masterlinqueautomation.com/ .

Automation also leads to improved quality in special purpose machine manufacturing. Automated machines are designed to perform tasks with precision and accuracy, resulting in a higher quality of output. Additionally, automated machines can detect errors and make corrections in real-time, reducing the risk of defects and errors in the final product.

Reduced costs are another benefit of automation in special purpose machine manufacturing. Automated machines require less human intervention, which means that the cost of labour is reduced. Additionally, automated machines can work faster and more efficiently than human operators, reducing the time and resources required to complete a task

Examples of automation in SPM Manufacturing Industry

The Special Purpose Machine (SPM) Manufacturing Industry involves the design and production of machines that are custom-built to perform specific manufacturing operations. Automation plays a crucial role in improving the efficiency and productivity of SPM manufacturing.

Here are some examples of automation in SPM manufacturing

CNC Machining: Computer Numerical Control (CNC) machines are widely used in SPM manufacturing. These machines are automated to perform various operations such as drilling, milling, and cutting with high accuracy and precision.

Robotics: Robotics is used in SPM manufacturing to automate various tasks such as loading and unloading of parts, welding, and painting. Robots can work around the clock and perform repetitive tasks with consistent accuracy, improving productivity and reducing costs.

,br>Vision Systems: Vision systems are used in SPM manufacturing to automate inspection tasks. These systems use cameras and software to identify defects, measure dimensions, and perform quality checks.

Automated Assembly Lines: Automated assembly lines are used in SPM manufacturing to streamline the production process. Parts are automatically fed into the line, and machines perform various operations such as welding, cutting, and drilling to assemble the final product.

Overall, automation in SPM manufacturing plays a crucial role in improving efficiency, reducing costs, and increasing productivity.

Finally, automation enhances safety in special purpose machine manufacturing. Automated machines can perform tasks that are dangerous or hazardous for humans, such as working with heavy machinery or handling hazardous materials. By automating these tasks, the risk of accidents and injuries is greatly reduced, creating a safer working environment for employees.

In conclusion, automation has transformed the special purpose machine manufacturing industry, providing numerous benefits such as increased productivity, improved quality, reduced costs, and enhanced safety. With the continued advancements in technology, automation is likely to play an even greater role in this industry in the years to come.